ACOFLEX Flexible Jaw or Spider Couplings

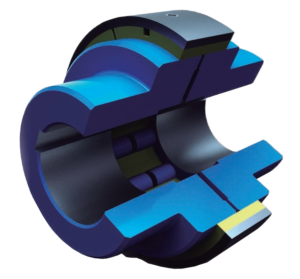

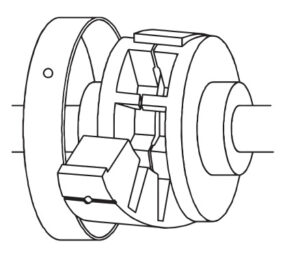

The Acoflex coupling is a flexible jaw coupling composed by four elements: two hubs, a elastomeric insert in between and the cover ring.

The hubs are manufactured in cast iron, each one with eight teeth, except the A-00 and A-0, which have four and six respectively.

The elastic split insert that fits over the hub teeth is manufactured with the best quality polyurethane compound, which can be supplied in three different qualities (standard, high temperature and high performance) providing the most suitable solution depending on the application requirements.

The steel cover ring is fixed to the insert with two setscrews assembling the coupling. The design allows a quick and easy installation and replacement without moving hubs and realigning either the driver or the driven equipment, reducing downtime.

The A series is the simplest construction of all Acoflex range couplings. However, more coupling configurations are available: with taper-bush bushings, spacer and double spacer arrangement, brake disc and brake drum configurations, and SAE flywheel assembly. Other designs are available upon request.

Features and benefits of Acoflex Jaw couplings

- Zero maintenance: No routine maintenance or lubrication required

- Quick and easy installation and replacement: The design allows a quick and easy element installation and replacement without moving hubs and realigning either the driver or the driven equipment, reducing downtime

- Long lasting: The elastic insert has an excellent resistance to chemicals and wear, with different polyurethane qualities available, obtaining a maximum working temperature range from -40 °C to +140 °C

- Safe: The flexible element is retained by the cover ring and there is no metal to metal contact between both hubs, avoiding to create any possible spark

- High misalignment capabilities: Compensates high axial, angular and radial misalignments

- Shock load and vibration absorption: The elastomeric insert absorbs the shock loads and vibrations transferred to the driven equipment.

Application fields of Acoflex Jaw Couplings

- Suitable for applications with high misalignments

- When downtime and maintenance expenses are critical

- When shock load and vibration transmission damping is necessary

- Useful in low and medium power rates

Types of elastic inserts for the Acoflex Jaw Coupling

The elastic inserts are manufactured with the best quality polyurethane elastomeric compound. Three Acoflex insert qualities and hardness are available, depending on the application:

| Quality | Hardness | Admissible Temperature | Insert Colour |

|---|---|---|---|

| Standard | 95º Shore A | -40 / +80º C | Yellow |

| High Temperature | 95º Shore A | -40 / +140º C | Red |

| High Torque | 97º Shore A | -40 / +80º C | Green |

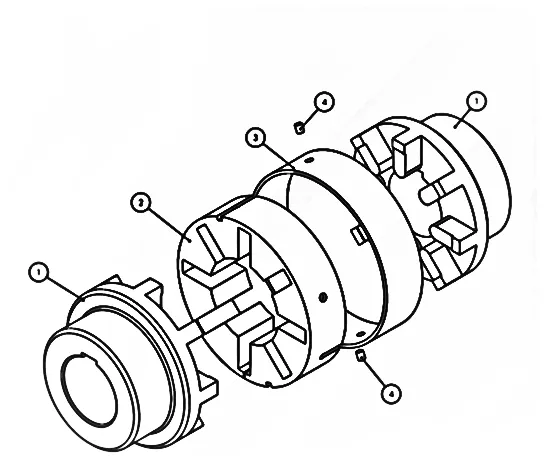

Components of Acoflex Jaw Coupling

| Component | Quantity | Description | Material |

|---|---|---|---|

| 1 | 2 | Hub | CG-25 |

| 2 | 2 | Elastic Insert | Polyurethane |

| 3 | 1 | Cover ring | Steel |

| 4 | 2 | Screw Set | Steel |

Storage and maintenance

The elastic inserts retain their mechanical properties and hardness characteristics for several years if stored in the correct conditions (dry and covered place). However, the colour of the insert may vary over time due to the light.

The couplings’ hubs and cover rings can be stored in the same conditions for several years for an indefinite time.

A periodic visual inspection of the coupling is recommended.

Disclaimer: Manufacturers' names or trademarks used on this website are for identification purposes only. RTT is not affiliated with these companies unless otherwise stated.